by FPDieulois :: 2025-11-10

Beyond Lithium-Ion: The Push for Sustainable Energy Storage

As the world races toward net-zero emissions, batteries face mounting pressure to deliver higher energy density,

faster charging, and eco-friendliness without relying on scarce resources like cobalt or nickel.

Lithium-ion (Li-ion) batteries dominate today, powering EVs and renewables,

but their liquid electrolytes pose fire risks, and mining strains supply chains.

Enter next-generation contenders: organic batteries from carbon-based molecules,

metallic ones leveraging abundant ions like iron and zinc, and bio-inspired designs mimicking nature's efficiency.

These promise safer, greener alternatives, with solid-state lithium evolving in parallel.

By 2030, experts predict a $100 billion market shift, driven by AI-accelerated materials discovery.

At the heart of this evolution are researchers like Ulrike Krewer, a professor at Karlsruhe Institute of Technology (KIT).

Her work on electrochemical modeling and diagnostics bridges lab curiosities to industrial scalability,

emphasizing lifecycle analysis for safer, sustainable cells—from lithium plating prevention to organic electrode optimization.

Krewer's teams use nonlinear frequency response to probe battery degradation,

informing designs that extend life while minimizing environmental impact.

Organic Batteries:Carbon's Green Revolution

Organic batteries swap metal-heavy components for tunable,

earth-abundant molecules like quinones or conjugated polymers, slashing costs and toxicity.

Unlike inorganic Li-ion, organics dissolve in electrolytes for flexible, lightweight packs—ideal for wearables or drones.

Their redox reactions, involving electron shifts in carbon frameworks, enable high power without rare metals.

A standout: bio-derived organics from lignin or cellulose, yielding 200-300 Wh/kg densities at 80% lower production emissions.

Recent advances include sulfonamide cathodes for Li-organic cells, cycling 1,000 times with 150 mAh/g capacity.

Krewer's contributions shine here; her modeling of organic electrosynthesis highlights kinetics in aprotic electrolytes, accelerating catalyst design for stable, high-rate organics.

In 2024, her KIT group demonstrated pressure-sensitive diagnostics to curb gas evolution in organic Li-ion variants, boosting safety for grid storage.

Challenges persist—organics' solubility limits longevity—but polymer binders and nano-structuring are closing gaps, targeting commercial pilots by 2027.

Metallic Batteries: Abundant Ions for Heavy Duty

Metallic batteries harness cheap, plentiful metals like iron, zinc, and sodium, ditching lithium's volatility for robust, recyclable chemistries.

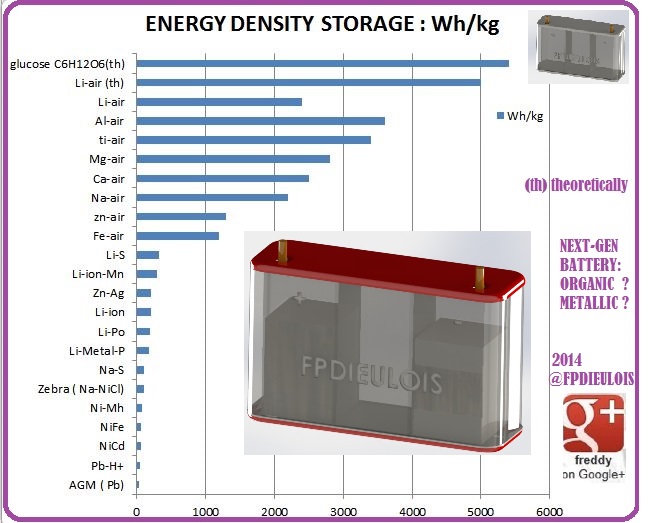

Iron-air batteries, for instance, react rust-prone iron with oxygen for 10x cheaper energy than Li-ion, hitting 1,000 Wh/kg theoretically—perfect for stationary storage.

Zinc-based systems, including zinc-air and zinc-ion, offer aqueous safety, with EnZinc's microsponge anodes doubling rechargeability

for EV packs under $50/kWh.AGM (Absorbent Glass Mat) batteries, a lead-acid evolution,

trap sulfuric acid in fiberglass mats for spill-proof, vibration-resistant power in hybrids or backups.

While not cutting-edge, AGM's 99% recyclability makes it a bridge tech, evolving into zinc-AGM hybrids for 2x cycle life.

Lithium's metallic future splits by state: liquid electrolytes enable today's 300 Wh/kg but risk dendrites;

solid-state versions use ceramics or sulfides for 500+ Wh/kg, fireproof packs.

Solid Power's sulfide cells, tested in 2025 BMW prototypes, charge in 15 minutes.

Krewer’s multiscale simulations predict solid-electrolyte interphases, curbing lithium metal's dendrite woes for 5,000-cycle endurance.

Liquid lithium persists in cost-sensitive apps, but solids could claim 40% EV market share by 2035.

Bio Batteries: Nature's Charge in Sugar and Beyond

Bio batteries draw from living systems, using enzymes or microbes to metabolize organics

like glucose (sugar) into electricity—non-toxic, self-replenishing power.

Glucose-oxygen fuel cells, inspired by mammalian metabolism, generate 100 mW/cm² via enzymatic oxidation,

recharging from body heat or food waste.

Virginia Tech's 2025 prototype powers implants indefinitely, harvesting blood sugar for 10x longevity

over Li-ion pacemakers.Anaerobic bio-batteries, like those from banana waste, employ bacteria (e.g., Geobacter)

in microbial fuel cells for portable, biodegradable units—outputting 50 mW for off-grid Africa.

Recharge via organic feedstock, they cut e-waste by degrading naturally.Krewer's exploratory

work on bio-electrodes aligns with this; her oxygen evolution models inform bio-cathodes, enhancing efficiency in glucose-based systems.

A 2023 KIT study modeled microbial-organic interfaces, revealing 20% higher yields through tuned pH—paving bio-batteries for remote sensors.

Emerging Materials: AI and Hybrids on the Horizon

Future materials blend paradigms:

AI-discovered porous oxides for multivalent ions (Mg, Al, Zn) promise 400 Wh/kg at ambient temps, per NJIT's 2025 breakthrough.

Lithium-sulfur organics hit 600 Wh/kg, while iron-phosphate solids scale for grids.Krewer's lifecycle research integrates these;

her 2024 algorithms diagnose hybrid cells, optimizing zinc-organic mixes for 2x safety.

CIC energiGUNE's metal-air catalysts (Ni, Fe) enable rechargeable zinc-air, targeting stationary dominance.

By 2040, expect sugar-recharged bio-metallics in homes, organic solids in EVs—sustainable, circular energy ecosystems.

< B > My Personal Blog < B > List of all my Blog posts < B >

(c)FPe COPYRIGHT @FPDIEULOIS 2025